Yini impahla ye-thermoplastic composite?

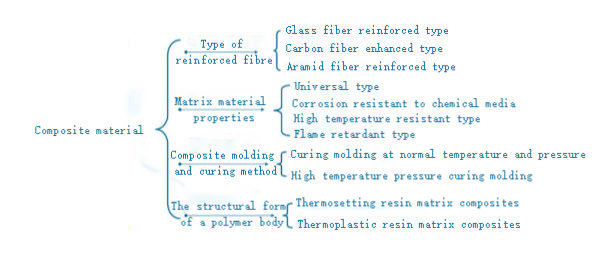

Eminyakeni yamuva nje, ukuthuthukiswa kwama-composites aqinisiwe we-thermoplastic asuselwa ku-thermoplastic resin kushesha, kanye nocwaningo kanye nokuthuthukiswa kwalolu hlobo lwezimpawu zokusebenza eziphezulu ziqala emhlabeni. Ama-Thermoplastic Composites abhekisela kuma-thermoplastic polymers (njenge-polyethylene (pe), i-polyamide (PA), i-polythene), izinto ze-polyther zenziwe nge-etheres ether. I-Fibrey, i-aryylon fiber, njll.) Njengezinto zokuqinisa.

Ama-Thermoplastic lipid akwenzeki ama-composites ikakhulukazi afaka i-granular ende eqinisiwe ye-granular (LFT) eqhubekayo ye-fiber eqinisiwe ye-MT kanye ne-fiber fiber okuqinisiwe kwe-thermoplastic composites (CMT). Ngokusho kwezidingo ezihlukile zokusetshenziswa, i-resin matrix ifaka i-PPE-paprt, i-peekPes, i-PEEKPI, i-PA kanye nezinye izinhlobo ze-thermoplastic zobunjiniyela, futhi ubukhulu bufaka zonke izinhlobo ze-rebcose ze-viblose ezifana ne-boron fiber. Ngokuthuthukiswa kobuchwepheshe be-thermoplastic resin matrix composite kanye nokubuyiselwa kwayo, ukuthuthukiswa kwalolu hlobo lwezinto ezihlanganisiwe kushesha. I-thermal supercompound ibalwe ngaphezulu kwama-30% wenani eliphelele lezinto ezihlanganisiwe zesihlahla matrix emazweni athuthukile eYurophu naseMelika.

I-Thermoplastic Matrix

I-Thermoplastic Matrix uhlobo lwe-Thermoplastic Material, inezakhiwo ezinhle zemishini kanye nokumelana nokushisa, ingasetshenziswa ekwenziweni kwezinto ezahlukahlukene zezimboni. I-Thermoplastic Matrix ibonakala ngamandla aphezulu, ukumelana nokushisa okuphezulu nokumelana kahle nokugqwala.

Njengamanje, ama-thermoplastic resins asetshenziswa kwinsimu yendiza ikakhulukazi amazinga okushisa aphezulu okulinganisela kanye nokusebenza okuphezulu kwe-resin matrix, kufaka phakathi i-peek, ama-PPS kanye nePei. Phakathi kwazo, i-Amorphoous Peyi isetshenziswa kabanzi ekwakhiweni kwezindiza kunama-semi-crystalline pps kanye ne-peek ngokushisa okuphezulu kokubumba ngenxa yokushisa kwayo okuphansi kokusebenza.

I-Thermoplastic Resin inezakhiwo ezingcono zokwelapha kanye nokuphikiswa kwamakhemikhali, izinga lokushisa eliphakeme, amandla aphezulu okulimala, ukuvumelanisa okuguqukayo, ukuqina kokulimala, kungavuselelwa ukuqina, ukubumba okuphindaphindekayo, ukubumba kanye nokulungisa izici.

Izinto ezihlanganisiwe ezakhiwa i-thermoplastic resin kanye nokuqiniswa kwezinto zinokuqina, ukuqina okuphezulu, ukumelana nomthelela omkhulu kanye nomonakalo. I-Fibrep PrePREG ayidingi ukuthi igcinwe ekushiseni okuphansi, isikhathi esingenamkhawulo sokulondolozwa; Umjikelezo Omfushane owakhayo, we-welding, ukusebenza kahle kokukhiqizwa okuphezulu, okulula ukulungisa; Imfucuza ingavuselelwa; Inkululeko yokwakheka komkhiqizo inkulu, ingenziwa ngesimo esiyinkimbinkimbi, yakha ukuvumelana nezimo nezinye izinzuzo eziningi.

Ukuqiniswa Kwezinto

Izakhiwo zezinhlanganisela ze-thermoplastic azinakuxhomekeka kuphela kwizakhiwo ze-resin kanye ne-fiber okuqinisiwe, kodwa futhi zihlobene kakhulu nemodi yokuqinisa i-fiber. Imodi yokuqinisa i-fiber yama-thermoplastic composites ifaka amafomu amathathu ayisisekelo: ukuqiniswa kwe-fiber emfushane, ukuqiniswa kwe-fiber ende nokuqiniswa okuqhubekayo kwe-fiber okuqhubekayo.

Ngokuvamile, imicu ehlanganisiwe ehlanganisiwe ingu-0,2 kuye ku-0.6mm ubude, futhi njengoba imicu eminingi ingaphansi kwamamitha ayi-70μma I-thermoplastics emfushane eqinisiwe ivame ukwenziwa ngokuxuba imicu ku-thermoplastic ebilisiwe. Ubude be-fiber kanye nokuqondisisa okungahleliwe ku-matrix kwenza kube lula ukufezekisa ukumanzisa okuhle. Uma kuqhathaniswa ne-fiber ende nezinto zokwakha eziqinile ze-fiber eziqinisiwe, ama-fiber amafushane alula ukukhiqiza ngokuthuthuka okuncane kwezakhiwo zemishini. Ama-composite ayi-fiber ahlanganiswe athambekele ekubunjweni noma akhishwe ekwakheni izingxenye zokugcina ngoba imicu eyisisekelo ibe nomthelela omncane ku-fluidity.

Ubude be-fiber of ama-composites amade ngokuvamile buyi-20mm, okuvame ukulungiswa nge-fiber eqhubekayo emanzi angena endaweni yokuphinda futhi athathe ubude obuthile. Inqubo evamile esetshenzisiwe inqubo yepulepusi, ekhiqizwa ngokudweba ingxubevange eqhubekayo ye-fiber kanye ne-thermoplastic resin ngokubumba okukhethekile okufe. Njengamanje, izakhiwo ezihlelekile ze-Fiber RepreForced Permoplastic composite zingafinyelela ngaphezu kwe-200mpa kanye ne-modulus zingafinyelela ngaphezu kwe-20gpa ngokuphrinta kwe-FDM, futhi izakhiwo zizoba ngcono ngokubumba komjovo.

Imicu kuma-composites aqinisiwe we-fiber aqinisiwe aqinisiwe "aqhubekayo" futhi ayahluka ngobude ukusuka kumamitha ambalwa kuya kumamitha ayizinkulungwane eziningana. Izihlanganisi eziqhubekayo ze-fiber ngokuvamile zihlinzeka ngama-laminate, ama-prepregs, noma izindwangu ezinokwehla, njll.

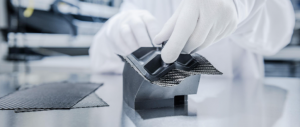

Yiziphi izici zama-composites aqiniswe nge-fiber-fiber

Inhlanganisela eqinisiwe ye-fiber yenziwe ngezinto zokwenziwa ze-fiber eziqinisiwe, ezinjenge-fiber yengilazi, i-carbon fiber, i-aramid fiber, kanye nenqubo yokubumba ye-matrid ngokusebenzisa i-winding, yokubumba noma inqubo yokubumba i-purtstring. Ngokwezinto eziqinisiwe eziqinisiwe, ama-composites ahlanganisiwe ajwayelekile angahlukaniswa nge-grain fiber ukuqiniswa kwe-composite (GFRP), i-carbon fiber ukuqiniswa kwe-composite (CFRP) kanye ne-aramid fiber ukuqiniswa kwe-composite (ANCP).

Ama-composites aqinisiwe wefayiji anezici ezilandelayo:

(1) amandla athile athile kanye ne-modulus enkulu;

(2) Izakhiwo ezibonakalayo ziqashelwe;

(3) Ukumelana nokuqina kokugqwala okuhle nokuqina;

(4) I-coefficient yokwandiswa kwe-thermal iyafana nalokho kukakhonkolo.

Lezi zici zenza izinto ze-FRP zingahlangabezana nezidingo zokuthuthuka kwezakhiwo zesimanje kuya kwezehlakalo ezinkulu, kodwa futhi zisebenza kabanzi ngezimo ezinzima, kodwa futhi zizobhekana namandla aphezulu kanye nemigwaqo ephakeme, nezinhlaka ezingaphansi komhlaba.

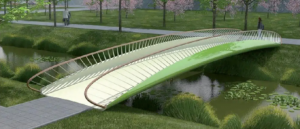

Ama-Thermoplastic Composites anamathemba amakhulu wokuthuthuka

Ngokombiko, imakethe yama-composites ye-Global thermoplastic kulindeleke ukuthi ifinyelele kuma- $ 66.2 billion ngo-2030, ngesilinganiso sokukhula sonyaka esingu-7.8% ngesikhathi sokubikezela. Lokhu kwanda kungabonakala ngenxa yokukhula komkhiqizo ku-Aerospace kanye nezimoto ezihlalweni nasekukhuleni okubonakalayo emkhakheni wezokwakha. Ama-Thermoplastic Composites asetshenziswa ekwakhiweni kwezakhiwo zokuhlala, ingqalasizinda nezindawo zokuhlinzekwa kwamanzi. Izakhiwo ezinjengamandla amahle kakhulu, ubulukhuni, kanye nekhono lokuvuselelwa futhi kubuyiselwe ukwenza ama-thermoplastic ahlanganise ama-composites elungele izinhlelo zokwakha.

Ama-Thermoplastic Composites azosetshenziselwa ukukhiqiza amathangi okugcina, izakhiwo ezingasindi, ozimele zewindows, izigxobo zocingo, izitimela, amapayipi, amaphaneli nezicabha. Imboni yezimoto ingenye yezindawo ezibalulekile zohlelo lokusebenza. Abakhiqizi bagxile ekuthuthukiseni ukusebenza kahle kwamafutha ngokubuyisela izinsimbi nensimbi ngama-thermoplastic angasindi. I-Carbon fiber, ngokwesibonelo, inesisindo esisodwa nesihlanu njengensimbi, ngakho-ke kuyasiza ukunciphisa isisindo semoto yonke. Ngokusho kweKhomishini YaseYurophu, i-Carbon Emiss Cap Target yezimoto izokhuliswa kusuka kumagremu ayi-130 ngekhilomitha ngama-95 ngekhilomitha nge-2024, okulindeleke ukuthi kwandise isidingo sezinhlanganisela ze-thermoplastic embonini yezokukhiqiza izimoto.

Ithemba lama-Thermoplastic Composites likhulu, futhi abakhiqizi basekhaya batshala imali kakhulu ocwaningweni nasekuthuthukisweni. Siyethemba ukuthi ngemizamo ehlangene yawo wonke umuntu ngokuzayo, ubuchwepheshe obuhlanganisiwe basekhaya bungaba sesimweni esiholayo samazwe omhlaba.

Isikhathi sePosi: APR-21-2023